Optimized according to the percentage of the aspirated product, the eductor’s viscosity, and the duration of the operation, there are several techniques for proportionally mixing various liquids.

The simplest, least expensive, and most used by firefighters uses the Venturi effect.

This effect is the consequence of a reduction in the flow section of the moving water which lowers the pressure until another liquid can be sucked in, then the premix passes through a regularly increased section which allows the pressure to rise again.

Regulating The Suction Percentage

The difficulty lies in the fact that a change in the supply pressure of the unit changes the proportion of suction.

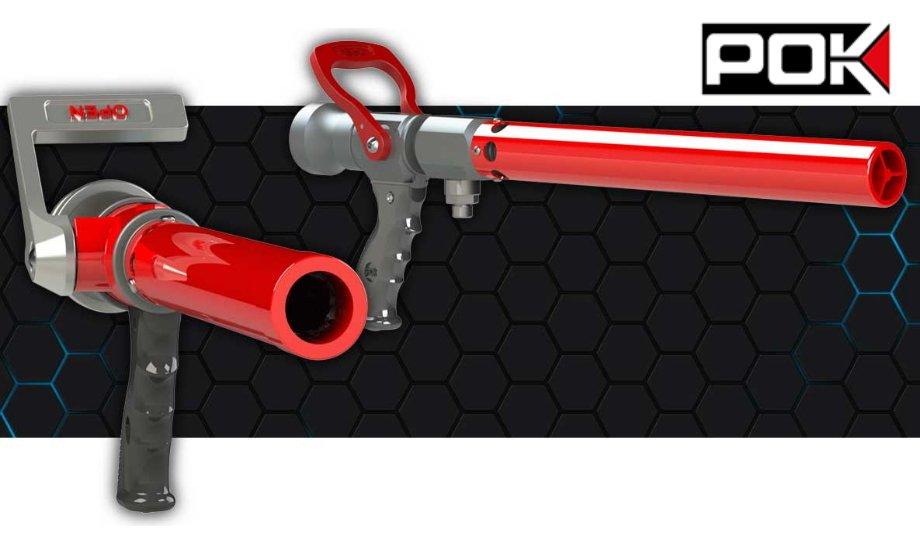

To remedy this, some manufacturers including POK® insert a valve between the water inlet of the eductor and the inlet of the liquid to be sucked in, which regulates the suction percentage.

In particular, this valve makes it possible to adjust the pressure loss (pressure drop) between the inlet and outlet of the eductor.

Valve Proportioners

The POK proportioners are set for a pressure drop of 35%. Other proportioners in the market have a pressure drop of around 38%. Valveless injectors are economical and relatively imprecise used by British and American fire services

All other units operate without a control valve are called injectors. It has a pressure drop greater than or equal to 40%, allowing it to operate over a wide range of supply pressures.

The valveless injectors are very economical and at the same time relatively imprecise, which is not necessarily a disadvantage with cheap foamers. The injectors are mainly used by the British and American fire services.

Usage As Per Economy

Valve proportioners are used in Germany and in Germanic regions with a better sense of economy.

The percentage of emulsifier in the premix is usually 3% with a knob that ranges from 1% to 6%, and even up to 7% on the Polish standard, but the Poles have chosen this rule to avoid introducing into their country the German, Austrian, Czech, and Russian productions that throughout history have invaded them; but some people claim that this is because of the poor quality of the emulsifier production.

Process To Operate A Pump

Below a percentage of 1%, a system called around the pump is used, which consists of taking the liquid under pressure from the pump outlet, passing it through an injector, and returning the premix to the pump feed.

The injector’s dosing adjustment gives proportions that can vary from 0.1% to 1% and is used to introduce retardants into the liquid to extinguish forest fires.

There are other processes where energy from pressure and flow rate is taken to operate a pump and allows very precise dosing with generally high costs and little used for foam production but rather in animal feed.